All our raw materials

have been certified by their manufacturer

Materials

We design products suitable for reuse, using recycled materials

and biodegradable and compostable green products

Certified products

We produce starting from certified raw materials and manufacture finished products that are certified by accredited laboratories.

In-depth knowledge

Over the years we have cultivated an in-depth knowledge of the legal provisions relating to the materials allowed for packaging, bags, multipurpose bags: all the raw materials we use have been certified by the manufacturer and subsequently the finished products made by us have been certified by accredited laboratories.

Focused on reusability

The company’s offer, strongly focused on the design of reusable products, aims at the same time to reduce the impact on environmental matrices, using “second life” materials made from waste recycling and to offer to its customers green products, such as ‘BioCom’ products, a 100% biodegradable and compostable alternative, Green PE products, polyethylene obtained from 100% renewable sources and of course biokraft paper.

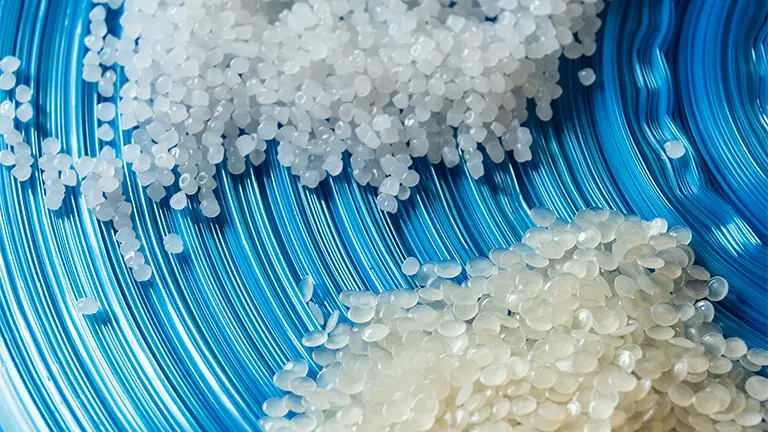

Plastic

A long-lasting beauty

Polyethylene is a flexible, economical, durable, and recyclable material, perfect for making multi-purpose packaging and shopping bags, reusable and able to guarantee an excellent aesthetic performance, which enhances the creativity and colors of every type of customization.

The same type of material can also be used to make light and cheap bags when the packaging must necessarily be unique. No raw material guarantees such low production and recycling costs, but of course the end of life of the product must be managed correctly and treated as a precious resource.

Shopping bag 100% beautiful and cheap

The plastic polymer has an excellent aesthetic performance but, above all, allows the bag to be reused several times and is a cheaper material than the alternatives (paper, textile materials). It is the printed plastic shopping bags that perform best with the use of this material. The printing carried out can be flexographic or screen printing, in this case also glittery, to add valuable elements to the product.

Bags and packaging in LDPE and HDPE always in accordance with the law

For our plastic products we use polyethylene LDPE (low density), flexible and transparent, and HDPE (high density), which has greater rigidity and opacity, extruded, if necessary, with higher percentages of recycled material, compared to the provisions of Legislative Decree 152/2006. All our plastic, multi-purpose and reusable shopping bags comply with the thicknesses required by current regulations, based on the model and the sector of use (food or no food).

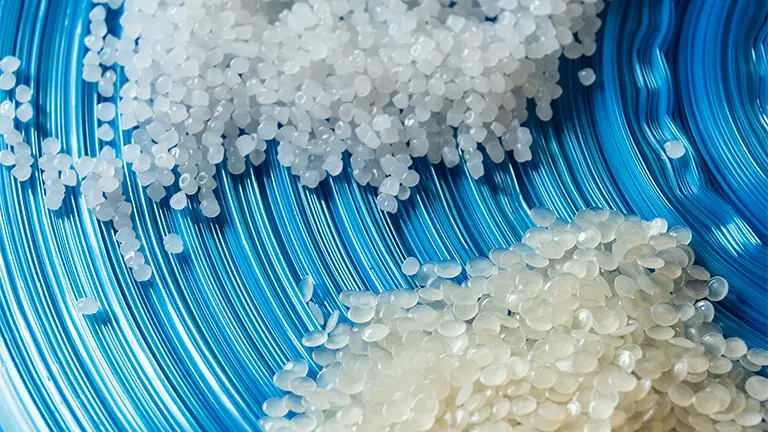

Biocom

Durable, zero-impact bags

How strong these ecological bags are! When the love for nature meets the desire for reliability, BioCom is born, our ecological line of bags and envelopes resistant like a traditional bag, but 100% biodegradable and compostable.

The use of certified compostable granule, without the addition of other resins and additives, determines a higher quality of the finished product, easily verifiable by comparing a PG Plast shopper to the most common products on the market.

The polymers used ensure full compliance with the marketing limits of sacks and bags imposed by national legislation.

Our research in ecological materials

The attention to the environment leads PG Plast to a constant research of materials that can be reused for a long time or guarantee a lower impact on environmental matrices, through the use of bio-based or totally biodegradable materials if included in the collection cycle of the organic fraction of urban waste, such as BioCom.

Bags and packaging in accordance with the law

The polymers used to produce biodegradable and compostable plastic films ensure full compliance with the performance limits for sacks and bags imposed by national legislation.

Our products are certified with the OK Compost Industrial® mark issued by TUV Austria, a mark that guarantees their full biodegradability in industrial composting plants.

The certification obtained considers all the components, from the bioplastic polymer to inks and additives used in the production cycles.

The reference point for the certification program is the standard defined by the harmonized standard UNI EN 13432: 2000 and the products with the OK compost logo comply with the established requirements of the European packaging directive (94/62 / EEC).

Green PE

Bags of vegetable 100% recyclable origin

Green PE is a 100% recyclable and ecological material, ideal for making shoppers and packaging materials that are durable and reusable.

GREEN plastic for eco-friendly bags

Green PE maintains the properties, performance, and versatility of fossil polyethylene, but capturing CO2 during its production instead of releasing it into the atmosphere. Its 100% vegetable origin allows, during the life cycle from the original material to the finished product, to reduce harmful emissions of greenhouse gases.

HDPE, LDPE and LLDPE. Technology and ecology.

Green Polyethylene combines high performance and workability.

Compared to traditional polyethylene, the main difference is that the ethanol used for Green PE is not produced by the processing of crude oil but derived from the processing of sugar cane. Therefore, each ton of Green PE produced determines a reduction in CO2 emissions of up to 3.09 tons contributing to the reduction of emissions of climate-changing gases (greenhouse gases).

The experiments conducted include different types of HDPE, LDPE and LLDPE, particularly suitable for bubble extrusion and film extrusion.

Green PE is recycled with an industrial process like traditional polyethylene, thus being 100% recyclable.

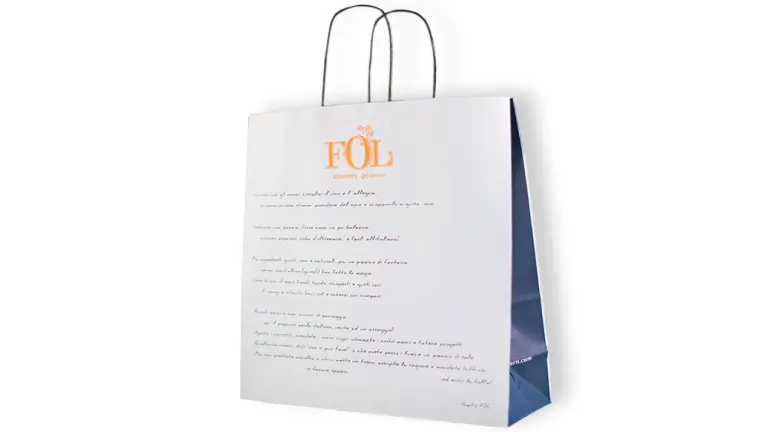

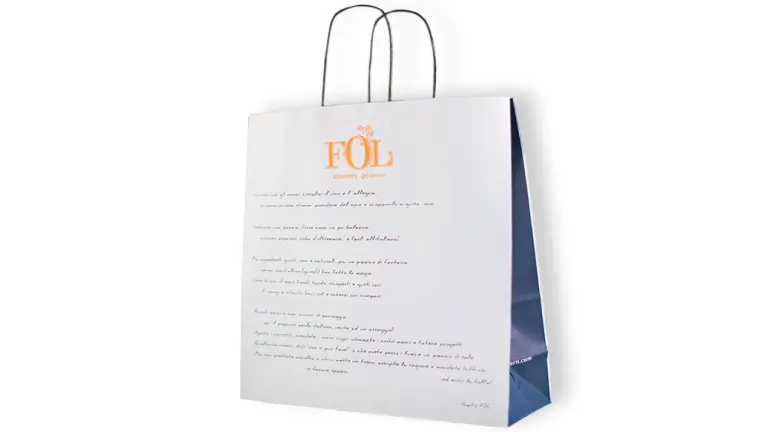

Paper

Paper packaging and shoppers

with many natural qualities

Paper allows many possibilities for customizing the finishes and support, in colors, processes and applications. Natural and renewable material, the paper we use in PG Plast is supplied by the best Italian producers and produced with respect for the environment.

Green card for our bags

Paper products consist of mainly vegetable raw materials, whose main components are natural and renewable. For this reason, after their use, they are recyclable, biodegradable and compostable.

Many types of printing

for custom shopping bags

The automatic paper bags can be printed in flexography up to 8 colors, while the manual ones can be customized with offset, hot or embossed printing. Further processing, such as painting, plasticizing, and embossing, as well as the application of handles of various materials, allow to obtain a unique shopping bag, which enhances the image of each company or store.